Have you ever tried cutting polycarbonate and ended up with a jagged mess? It’s frustrating, right? Polycarbonate, that tough, clear plastic, is used for everything from windows to protective shields. But cutting it neatly with a circular saw can be tricky. The wrong blade can chip the plastic, leaving you with a project ruined and wasted material.

Choosing the best circular saw blade for polycarbonate is a common problem. Many blades claim to do the job, but they don’t always deliver clean cuts. You might face chipping, cracking, or even melting. This can lead to wasted time, money, and a lot of headaches. Knowing which blade to use is key to success.

This blog post is your guide to finding the perfect blade! We’ll explore the best options and explain why they work. You’ll learn about blade tooth counts, materials, and other important features. By the end, you’ll know exactly what to look for and how to get smooth, professional-looking cuts every time. So, let’s dive in and make your polycarbonate projects a breeze!

Our Top 5 Best Circular Saw Blade For Cutting Polycarbonate Recommendations at a Glance

Top 5 Best Circular Saw Blade For Cutting Polycarbonate Detailed Reviews

1. IVY Classic 35050 Swift Cut 7-1/4″128 Tooth Aluminum & Plastic Cutting Circular Saw Blade with 5/8″ Diamond Knockout Arbor

Rating: 9.1/10

The IVY Classic 35050 Swift Cut circular saw blade is built to cut through aluminum, plastic, and vinyl siding. This blade has 128 teeth and is designed for materials up to 1/8″ thick. It’s made of high carbon alloy-steel. The blade features expansion slots to help prevent warping. It also has a 5/8″ diamond knockout arbor.

What We Like:

- The blade cuts light gauge aluminum, plastic, and vinyl siding.

- It has precision ground teeth for smooth cuts.

- Expansion slots help prevent the blade from warping.

- The blade is made of high carbon alloy-steel.

What Could Be Improved:

- It is only for materials up to 1/8″ thick.

- You’ll need a different blade for thicker materials.

This Swift Cut blade is a good choice for cutting thin materials. Remember to check the direction of the arrows before you start cutting.

2. CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade for Plywood

Rating: 9.0/10

The CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade (CMAS2725140) is built for cutting plywood, OSB, and plastic. This blade has a lot of teeth for a fine finish. It is made to make smooth and accurate cuts. This blade is a good choice for your projects.

What We Like:

- MAINTAIN CUTS: The fully-hardened plate helps keep cuts true.

- PRECISION: The precision-ground teeth make cuts smooth and accurate.

- EXTENDED LIFE: Heavy-gauge high carbon steel helps the blade last longer.

- ACCURATE CUTS: The fully flattened plate helps make fast, accurate cuts.

What Could Be Improved:

- We need more information about the blade’s performance on different materials.

- The price compared to other blades could be a factor.

This CRAFTSMAN blade seems like a good option for your cutting needs. It should provide clean and precise cuts for your projects.

3. DEWALT Circular Saw Blade

Rating: 8.7/10

The DEWALT Circular Saw Blade, 7 1/4 Inch, 16 Tooth, Metal Cutting (DW3330) is made for cutting metal. This blade is strong and built to last. It is designed for tough jobs. The blade is great for both professionals and DIYers.

What We Like:

- The teeth are sharpened for quick and smooth cuts. This helps the blade cut easily.

- A special coating prevents rust. It also cuts down on friction.

- The blade’s body is thick. This makes it more durable. You can use it for heavy-duty work.

- The steel body is fully hardened. This keeps the blade from bending or getting stuck.

What Could Be Improved:

- The number of teeth may not be ideal for every metal cutting job.

In conclusion, the DEWALT DW3330 is a solid choice for metal cutting. This blade is a good option for people who need a reliable and long-lasting saw blade.

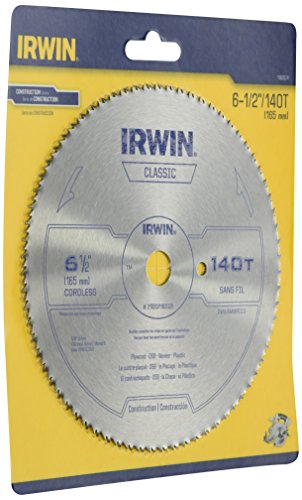

4. Irwin Tools Irwin 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic

Rating: 9.2/10

The Irwin Tools Irwin 11820ZR saw blade is made for cutting plastic, plywood, and veneer. It has a lot of teeth – 140! This helps make smooth cuts. The blade is 6-1/2 inches wide, and it fits saws that use a 5/8-inch arbor. This saw blade is built to give clean cuts. It is a good choice for projects where you want a nice finish.

What We Like:

- The many teeth make smooth cuts.

- It is great for plastic, plywood, and veneer.

- It fits many common saws.

- It helps you get clean cuts.

What Could Be Improved:

- The blade might not be good for all types of wood.

- You may need to buy it online.

This Irwin saw blade is a good option for anyone who works with plastic, plywood, or veneer. It is a great tool to have for your projects.

5. 3Pack 4-1/2 Inch 120T Circular Saw Blade 3/8 Inch (9.5mm) Arbor

Rating: 8.7/10

Need a smooth and fast cut? This 3-pack of 4-1/2 inch circular saw blades is here to help! These blades have 120 teeth. They are made for plywood, OSB, paneling, and vinyl siding. The blades are designed for a clean cut. They fit most corded and cordless saws with a 3/8 inch arbor. Get ready to say goodbye to splinters and hello to clean edges.

What We Like:

- The 120 teeth give you precise cuts.

- The thin kerf helps with smooth cuts.

- These blades are made of tough alloy steel. This means they stay sharp longer.

- They cut plywood, OSB, paneling, and vinyl siding smoothly.

- You will get clean cuts without splinters.

- The 3/8 inch arbor fits many saws.

What Could Be Improved:

- The description doesn’t mention the specific type of alloy steel.

These saw blades are a good choice for anyone needing clean cuts. They are perfect for DIY projects. You can use them for many materials!

Choosing the Best Circular Saw Blade for Polycarbonate

Cutting polycarbonate can be tricky. You need the right tools. This guide helps you pick the best circular saw blade. It will make your cuts smooth and clean.

Key Features to Look For

You need to know what to look for in a saw blade. Here are some important features:

- Teeth Count: Look for blades with many teeth. This is important. More teeth mean smoother cuts. For polycarbonate, choose blades with at least 80 teeth. Some blades have even more!

- Tooth Design: The tooth shape matters. Look for blades with a Triple Chip Grind (TCG) or a Flat Top Grind (FTG). These designs work well with plastics. They reduce chipping and cracking.

- Blade Material: The blade material is important. Carbide-tipped blades are a great choice. They last longer than steel blades. They stay sharp for many cuts.

- Blade Diameter: Make sure the blade fits your saw. Check your saw’s manual. It will tell you the right blade diameter. Common sizes are 7 ¼ inches and 10 inches.

- Arbor Size: The arbor size is the hole in the middle of the blade. This hole fits on your saw’s shaft. Make sure the arbor size matches your saw.

Important Materials

What the blade is made of is important. Here’s what you should know:

- Blade Body: The blade body is usually made of steel. Good steel blades are strong and stable.

- Teeth: The teeth are usually made of carbide. Carbide is very hard. It stays sharp for a long time. This is perfect for cutting polycarbonate.

- Coatings: Some blades have coatings. These coatings help reduce friction. They can also prevent the blade from getting hot. This is good for polycarbonate.

Factors That Improve or Reduce Quality

Some things make a blade better. Other things make it worse. Here’s how to tell the difference:

- Quality Improves With:

- A high tooth count.

- Carbide teeth.

- A well-made blade body.

- Proper tooth design (TCG or FTG).

- A good coating.

- Quality Reduces With:

- A low tooth count.

- Steel teeth.

- A poorly made blade body.

- The wrong tooth design.

- No coating.

User Experience and Use Cases

How the blade works is important. Here’s what to expect:

- Smooth Cuts: A good blade will cut polycarbonate smoothly. You shouldn’t see many chips or cracks.

- Less Heat: The blade shouldn’t get too hot. Heat can melt the polycarbonate.

- Easy to Use: The blade should be easy to install on your saw. It should cut straight lines.

- Use Cases: You can use these blades for many projects. You can cut polycarbonate sheets for:

- Making windows.

- Building greenhouses.

- Creating signs.

- Making protective covers.

FAQ: Your Questions Answered

Q: What kind of teeth should my blade have?

A: Look for blades with TCG (Triple Chip Grind) or FTG (Flat Top Grind) teeth. These designs work best.

Q: How many teeth should the blade have?

A: Aim for a blade with at least 80 teeth. More teeth often mean smoother cuts.

Q: What is the best blade material?

A: Carbide-tipped blades are the best choice. They last longer and stay sharper.

Q: What size blade do I need?

A: Check your saw’s manual. It will tell you the right blade diameter for your saw. Common sizes are 7 ¼ inches and 10 inches.

Q: How do I install the blade?

A: Follow the instructions in your saw’s manual. Always unplug your saw before changing the blade.

Q: What safety gear should I wear?

A: Wear safety glasses to protect your eyes. Use hearing protection to protect your ears. Wear a dust mask to avoid breathing in dust.

Q: How do I make sure the cuts are straight?

A: Use a guide or a straight edge. Make sure the polycarbonate is held firmly in place.

Q: What if the blade gets hot?

A: If the blade gets too hot, slow down. Let the blade cool down. Consider using a blade with a coating to reduce friction.

Q: Can I use this blade for other materials?

A: Yes, these blades can also cut other plastics and some non-ferrous metals. But, always check the blade’s specifications.

Q: How do I store the blade?

A: Store the blade in a safe place. Protect it from moisture. Keep it away from other tools that could damage the teeth.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.